| Specification | Details |

|---|---|

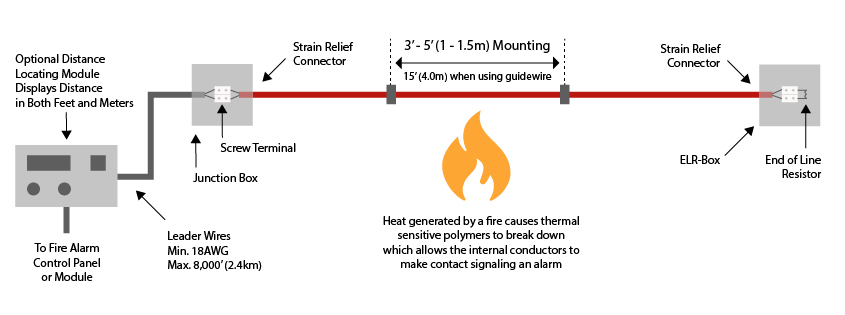

| Detection Method | Linear Heat Sensing (LHS) |

| Cable Length | Can exceed 1 km |

| Installation Type | Fixed / Flexible deployment |

| Controller Complexity | Low |

| Fire Location Detection | Available (distance-based) |

| Output Signal | 4-20mA (optional) |

| Compatibility | Works with most fire panels |

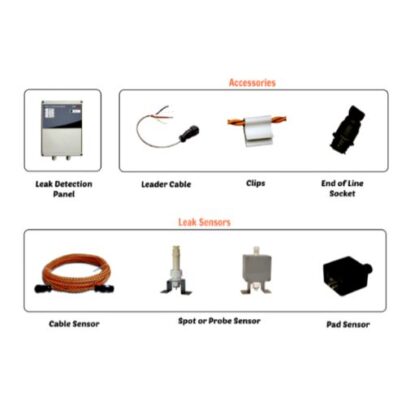

| Applications | Building fire alarms, Industrial plants, Tunnels, Conveyor belts, Mobile machinery |

| Response Time | Up to 30 seconds |

| Compact Design | Small and space-efficient |

This LHS Cable Fire Detection System by Hanumaa Protek is an efficient, low-maintenance solution for large-scale fire detection, ensuring safety and reliability in diverse applications.

Reviews

There are no reviews yet.